Home

About Us

Services

Products

Blog

contact us

Home

About Us

Services

Products

Blog

contact us

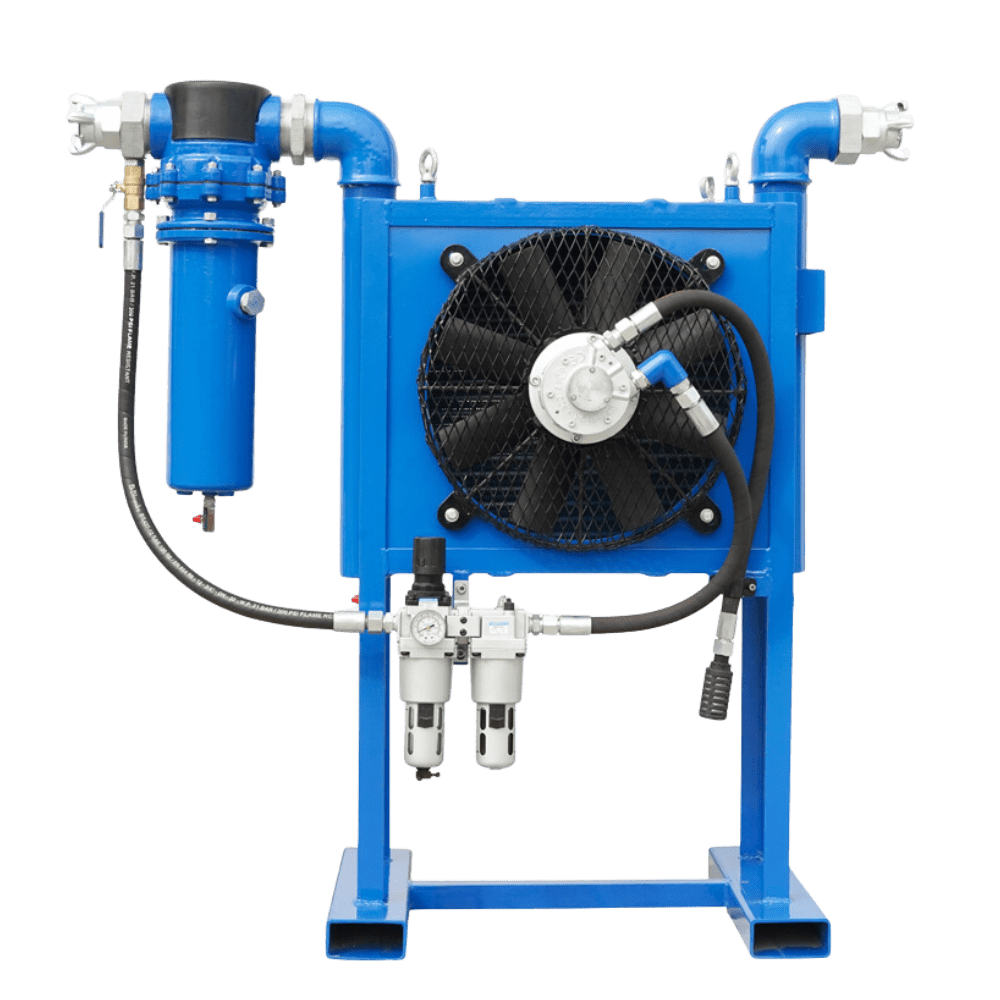

SpeedBlast’s compressed air after cooler efficiently removes moisture from compressed air during blasting. Without cooling, hot and moist air can cause equipment damage, abrasive clumping, and reduced performance. By passing air over the heat exchanger, the cooler condenses water vapor into liquid, which is then separated by the moisture separator. This ensures consistent and high-quality air supply for industrial operations.

This after cooler is essential for applications that depend on high-quality compressed air, including:

By removing moisture and regulating temperature, the After Cooler RA significantly improves process efficiency.

At SpeedBlast, we provide multiple models of after coolers to fit diverse project needs. Whether you require a RA 250 after cooler for heavy-duty operations or a RA 80 after cooler for small compressor setups, we ensure durability, efficiency, and superior performance.

Explore more about our company: Company Profile (PDF), Blogs, or Contact Us.

It cools compressed air, turning water vapor into liquid and removing it to prevent moisture-related problems in blasting and painting operations.

The RA 250 is ideal for heavy-duty operations, RA 120 for medium tasks, and RA 80 for smaller compressor setups. Contact our team for guidance.

Yes, the design is user-friendly with easy cleaning, reducing downtime and ensuring consistent efficiency.

Yes, it’s also useful in painting, shipbuilding, and other industries requiring clean, dry compressed air.